Spis treści

Presentation of SCADA Software: Asix Example

Asix is a platform for HMI/SCADA/MES systems developed by ASKOM since 1994. It is designed for creating and implementing industrial IT systems for enterprises, processes, production lines, machines, and devices.

The primary application of Asix is SCADA – for operator stations to directly supervise and control processes. It allows the acquisition of measurement data from programmable controllers, meters, and other measurement devices. Commands for starting and stopping drives are sent to controllers, and analog and binary data trends are recorded along with an alarm log. Using Asix, HMI-class applications for operator panels can also be implemented. The platform also supports online production tracking, calculating performance and quality indicators, data analysis, and reporting to ERP systems.

Key Features of the Asix Platform

The Asix platform offers a wide range of features, making it an ideal solution for various industries. Key features include:

- Visualization,

- Redundant data collection channels,

- Recipe management and event archiving,

- Production monitoring and tracking,

- Control,

- Reporting and graphical data presentation,

- Internet visualization,

- Application validation, control registration, and permissions management,

- Efficient data archiving,

- Alarm management,

- Multi-language support,

- Remote notifications.

One Application – Different Permissions

The Asix platform allows the use of a single SCADA application, but the available information and possible actions depend on the location of its execution and the user's role.

The wide range of tools and functions offered by the application, combined with a precise permission control system, allows for:

- Customizing the range of functions available to the user based on their needs and competencies.

- Flexibly modifying the scope of functions and privileges, which can overlap and complement each other.

Extensive Reference List

The Asix platform is an excellent solution for various industries, ranging from standard supervision and control applications to advanced monitoring systems. This is confirmed by over 16,000 licenses sold, used in the following sectors:

- Energy and heating,

- Food industry (dairy, meat, confectionery),

- Chemical and machinery industries,

- Coke production,

- Municipal infrastructure,

- Smart buildings,

- Telemetry systems,

- Automotive industry,

- Metallurgy.

System Description

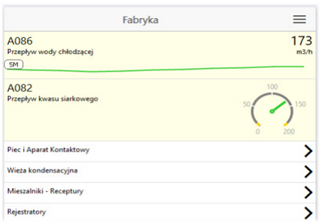

Analog Measurements and Binary Signals

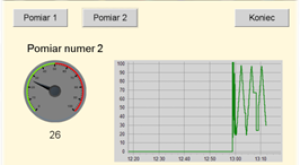

Current measurement values can be displayed numerically or as graphical objects representing the measurement in an analog form. Typically, applications use measurement panels, which are small windows providing concise information about the current measurement state, technological limit values (modifiable), and a trend history chart. Measurements can thus be presented in various formats and in multiple locations within the application. Binary signals are used to reflect the status of devices and control them – for instance, information about drives, activation states, readiness for operation, electrical readiness, or limit switch breaches.

Data Archiving

Data archiving is performed by the historian module, Aspad, which efficiently collects analog and binary data trends. The capacity of the online archive available on the operator's or process dispatcher’s computer is limited only by the size of the computer's disk and, in practice, can encompass historical data spanning many years. The historian was enhanced in version 9 to process and record current data with a precision of 100 nanoseconds. The actual data recording frequency depends on the communication interface's data acquisition speed.The designer has the option to choose the method of data archiving: either archiving in the internal Aspad module format, which ensures real-time data compression and redundant data removal, or archiving in an MS SQL database. Data is saved in UTC (Universal Coordinated Time), ensuring consistent timestamps regardless of daylight saving changes. This approach allows data from distributed systems in various time zones to be visible in each zone with the correct local time. Archived data is made available as raw data or aggregates for other Asix platform modules and third-party software.

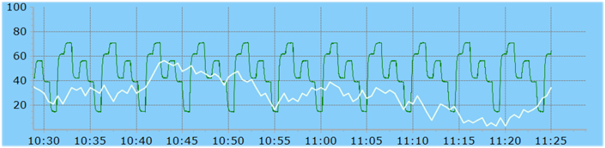

Data Trends

A tool for in-depth analysis of historical data is the AsTrend program. It allows displaying, reviewing, and printing time trends of selected variable sets and is used for preparing „graphical reports” on system performance. AsTrend can be used as an integral part of the visualization system or as a standalone program, even in a web browser, with access to the data archive on a local computer or remotely over a network. Additionally, it facilitates quick localization of relevant data segments using an intelligent browsing method, which composes trends based on aggregate values calculated and provided by the archiving module.

AsLogger - High-Frequency Data Recorder

Standard Asix licenses allow continuous data archiving with a resolution of up to 100ms. For cases where higher-frequency data collection is required, the additional AsLogger module can be used. Its operation is based on recording short-term data series in an SQL database. Complete data series must be prepared by the measurement device and are then read by Asix communication drivers. The high-frequency mode of AsLogger is supported only by selected electrical protection drivers.

Measurement Charts

Data from the Aspad module serves as the basis for creating measurement charts directly on technological diagrams. Operators can customize these charts according to their needs by changing the visible time horizon, navigating through history forward and backward, zooming in, or reading specific past values. Operators can also overlay a reference curve onto the current trend and instruct the system to read successive settings from this curve and send them to the controller to precisely execute the desired program for controlled parameter changes.

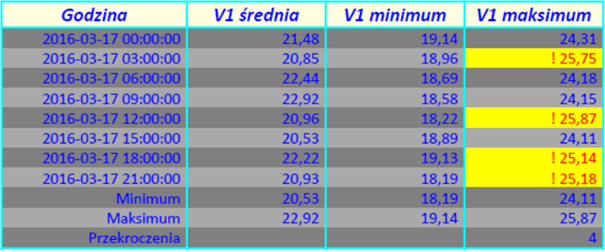

Reports

Reporting on process and production performance is a fundamental requirement for any computer supervision system. The minimum requirement includes operational reports, which are typically limited to tabular summaries of average, instantaneous, or selected aggregate values.

Today, systems are also expected to provide advanced reports for management teams. These reports should include synthetic summaries that combine data from various applications operating within the enterprise, enriched with in-depth data analysis and statistical processing. Reports should allow for information exploration, enabling increasingly detailed insights into the situation. Management also requires quick access to reports at any time and from any location. This is facilitated by the ability to publish reports on a local network or the Internet, making them accessible through a web browser.

Asix fully meets these requirements, exceeding standard solutions by offering several methods for generating reports, such as:

- Microsoft SQL Server Reporting Services,

- MS Excel,

- AsTrend,

- Script-based reporting systems.

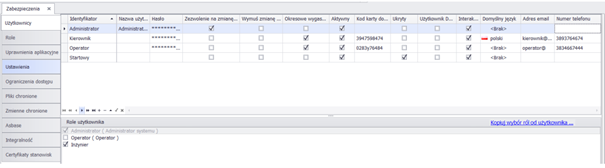

Application Usage Control System

The system is implemented through a central user login and permission control mechanism based on user roles. Each role determines specific user permissions. Only users authorized through login can operate the application. Any command or action issued by a user is executed only if the user possesses the necessary permissions. This mechanism can restrict various functionalities, including control execution, opening of synoptic screens, visualization of restricted variable values, access to reports, project application files, or transitioning to project editing mode. Roles initially prepared by the application designer can later be freely assigned to new or existing users by supervisory staff (administrators) during system operation.

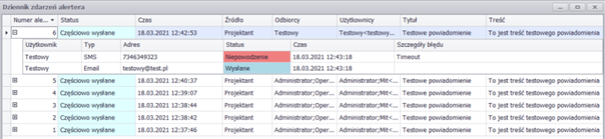

AsAlert - Remote Event Notification Module

Supervisory staff often work on a duty system, where they are not required to be present on-site. However, they must be reliably and promptly informed about abnormal system operations or failures. The AsAlert module is helpful in such situations, as it selectively signals emergency states. A list of alarm message recipients and a notification schedule ensure that information about a hazardous state reaches the appropriate person at the right time. Notifications can be delivered to recipients through various methods:

- As standard email via the Internet and the SMTP protocol,

- As SMS messages to mobile phones via GSM networks.

Recipe Management and Event Data Archiving

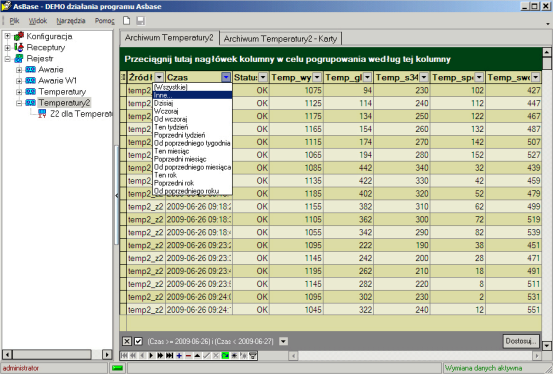

The Asix platform provides a specialized database management tool – AsBase, which, in collaboration with Microsoft SQL Server, facilitates easy application of recipes and registration of pre-defined data records, both manually and automatically.

A distinctive feature of the AsBase module is its fully interactive parameterization and operation. Application developers are not required to have specialized knowledge of database creation. The entire application-building process is carried out through data input in the module's dialog windows.

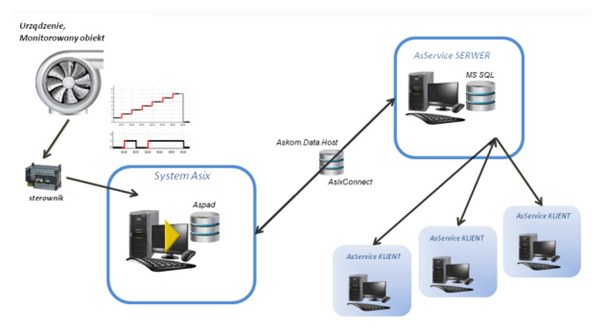

Production Resource Management

Optimal utilization of production resources requires access to information about resources and their usage statistics. The AsService module enables the registration of operating times and the number of activations of devices based on data collected from the Asix application. This allows for monitoring the need for maintenance activities, generating alerts and reports related to threshold breaches, and gathering technical and inventory data for each supervised device.

The foundation of the AsService module's functionality is the device and machinery registry, which allows for collecting and appropriately grouping data about all devices. All information generated and processed within the AsService module (meter states, maintenance activities, operation history, etc.) should correspond to the devices included in the aforementioned registry.

For each device, it is possible to specify a set of electronic documents related to its operation, such as technical manuals, user guides, test protocols, technological schematics, and more.

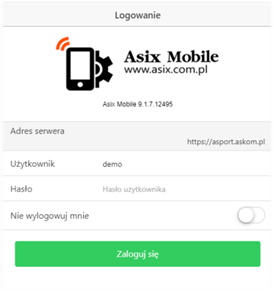

Monitoring and Control Using Mobile Devices

The Asix Mobile module extends the set of tools and programs available on the Asix platform with functionalities designed specifically for mobile devices such as smartphones or tablets.

Asix Mobile allows the creation of a fully functional interface for visualizing selected measurements of the controlled object and managing its operation. The design and operation of the graphical interface have been optimized for use on devices with small screens. Special emphasis has been placed on efficiently utilizing touch screens.

With Asix Mobile, users gain instant access to data, regardless of their location. It enables monitoring of real-time measurement values and viewing their historical changes. If necessary, users can intervene in the process by sending remote controls or setting adjustments. Alarm states are also monitored, including the ability to confirm their acknowledgment. Additionally, the notification system allows users to monitor the object without opening the Asix Mobile application—notifications about changes in selected alarm states can be sent automatically as system notifications displayed on the user's device.

Interactive Application Design Environment

The Asix Evo application design environment features a user-friendly and intuitive interface. Both system visualization configuration and application parameterization are performed using a single tool. Designers can modify applications on-site at any time, even without taking them offline. Application design, configuration, visualization building, and real-time editing are carried out through dialog windows with a tab system that organizes and clearly groups all options responsible for different functional areas of the application. This system guides designers seamlessly through the process of correctly declaring the required parameters.

Network Publishing

A SCADA application on the Asix.Evo platform can include presentation screens tailored for various users, such as object operators, maintenance staff, and production managers. It can consolidate applications from different objects into a single synthetic (comprehensive) project executable in MS Windows. The system can be configured so that the desktop version of the synthetic application is available on every computer in the plant network with the Asix system installed.

If that's not sufficient, the synthetic application, along with analytical tools (detailed AsRaport reports, alarm analysis in AsAlarm, and trends in AsTrend), can be easily published on a local network or the Internet, running seamlessly in a web browser. No application conversion is required, and its functionality remains intact. Web-based versions of applications, executed in HTML5 mode, are compatible with all modern browsers, including Edge, Mozilla Firefox, Google Chrome, and Opera.

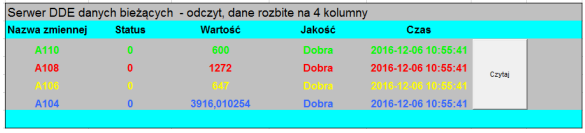

System Openness

Asix ensures system openness, allowing direct access to data from other applications/programs adhering to data exchange standards in the Windows environment. The AsixConnect module acts as a mediator between Windows operating system applications and the Asix application. It provides access to Asix system data—current, archived, alarms, and variable definitions.

In the Windows environment, data access is possible via protocols such as DDE, OLE DB, and OPC/OPC UA. Automation servers are available for Windows/Visual Basic, and .NET servers are available for Windows/Visual Studio. On the Internet/Intranet, data access is facilitated by the Web Services server.

This example demonstrates how to access current application data in the Asix system using the DDE server. To ensure the example works, the DDE server must be started beforehand.

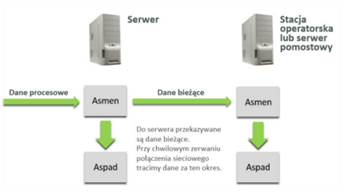

Redundancy and Multi-Station Applications

Asix has been designed with control systems in mind, placing great emphasis on system stability, internal mechanisms for verifying the correct operation of individual modules, and redundancy to minimize the impact of hardware failures. Specifically, Asix is prepared by default to create redundant structures in a „hot reserve” configuration. In this setup, two or more supervisory computer stations connect to the object through separate communication channels, independently performing data acquisition and archiving of process variables, as well as maintaining their own synchronized copies of the event and alarm logs.

Such a configuration of redundant Asix stations, when connected via an Ethernet network, becomes resistant to failures, including:

- Physical communication channel failure – a station experiencing such a malfunction automatically switches to data acquisition from a redundant station via the Ethernet network, allowing supervisory stations to continue functioning as equals.

- Supervisory station failure – until the failure is resolved, the process is monitored by the remaining stations. Upon restoring the computer to operational status, its data archive and event and alarm logs are automatically updated (synchronized).

It is also worth noting that pre-configuring pairs of computers operating in reserve mode is not required. When the need to switch to a backup channel arises, the operator station automatically detects a computer in its vicinity to retrieve data via the network. The switch to the backup channel and the return to the primary channel after repair can be signaled by sending an alarm notification.